Company introduction

We are located in Jiangyin city, Jiangsu province, specializes in

manufacturing various types of high speed, high precision roll

forming machines, with more than 20 years’ experience. It has

gained highly praise by customers from all over the world, due to

top quality and competitive price of the products. Company

principle: top quality, low price.

We a professional manufacturer of cold forming equipment

(especially high difficulty cold formed steel), wins the trust of

customers by its honesty, pragmatic operation philosophy, advanced

technology, innovative design thinking, excellent quality, superior

after sales service, competitive price, etc.

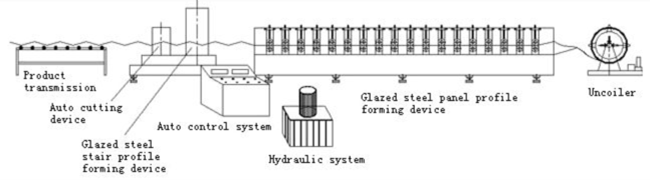

Main products

We mainly produce all kinds of roof/ wall tile roll forming

machine, C purlin, Z purlin, C&Z interchangeable purlin roll

forming machine, uni channel forming machine, rack

shelf roll forming machine, guardrail roll forming machine,

cable tray roll forming machine, metal deck roll forming machine,

down pipe roll forming machine, rolling shutter door roll forming

machine, auto stacker, EPS/PU sandwich panel production line, slitting line, cut to length

line, tube mill, etc, mainly in construction use.

After sale service

1). Engineer will give free training lessons to labors in buyer’s

factory.

2). The Buyer will buy the round-trip air ticket for Engineer if

visa application is approved. The buyer is also responsible to bear

expenses generated, e.g. visa formalities, meals, accommodation and

allowance of USD100 for engineer per day.

3). During this guarantee period, we will provide spare parts

without any charge in case of quality discrepancy caused by us. If

the malfunctions are caused by your incorrect operations, we will

provide the buyer spare parts at cost price.

4). We will charge the buyer cost price of spare parts beyond one

year and provide long-term technical guide.

Photo of the Factory

Our clients